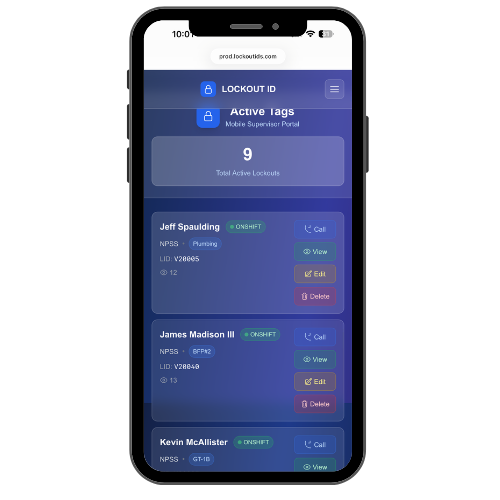

The lock out ID is a very good product it keeps the LOTO tag system looking clean, organized, and professional. It eliminates not being

able to read a tag and having to guess information. I would suggest for future usage on large jobs, that each unit is given their own

login to keep down on having to sort through all the other unit tags. As with all tech apps I see the ability to expand the usage of this

software to streamline the LOTO process even further (perhaps a digital login sheet for one item). I feel further usage and refinement of

this will definitely make us look like the world class company we are .”

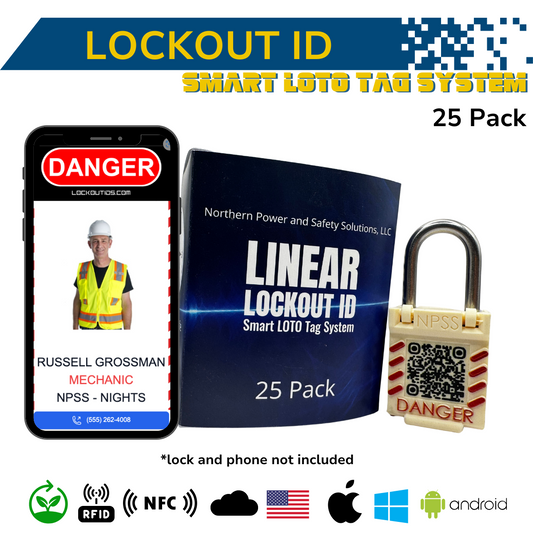

LOCKOUT ID by Northern Power and Safety Solutions is pioneering a significant shift in how we approach Lockout Tagout (LOTO)

systems. Typically, the primary concern has been compliance with plant owners' standards, often relegating workers' safety to a

secondary role. However, LOCKOUT ID disrupts this norm by prioritizing the safety and protection of workers. This modern solutio n

streamlines, enhances, and organizes the LOTO process, providing an invaluable tool for our managers, foremen, and supervisors at Gulf

Turbine Services (GTS). It champions the cause of ensuring safe working conditions through the use of distinctive digital tags for each

employee. At GTS, we take pride and satisfaction in incorporating LOCKOUT ID into our safety procedures. This innovative tool confronts

the long-standing challenge of deciphering handwritten tags and labels affected by various environmental conditions. It simplifies the

LOTO management process while also making audits more efficient and precise. LOCKOUT ID not only conserves time but also alleviates

the common complications that come with traditional LOTO procedure. LOCKOUT ID is an embodiment of the idea that workers' lives

are priceless, and that investing in their safety is paramount. GTS wholeheartedly shares this belief and eagerly anticipates the

improvements in safety that LOCKOUT ID brings to our daily operations.”

Northern Power and Safety Solutions has truly outdone itself with its creation of the LOTO IDs. As a company committed to enhancing

safety in the workplace, its innovative LOTO IDs have revolutionized safety procedures in the field. From the moment we implemented

the LOTO IDs, it was evident that they were designed with practicality and efficiency in mind. The system is intuitive and easy to use,

allowing our team to quickly identify and isolate energy sources during maintenance and repair work. Gulf Turbine Services has found

immense value in the LOTO IDs provided by Northern Power and Safety Solutions. As a company operating in the highly specialized field

of turbine services, the implementation of the LOTO IDs has proven to be a game-changer for Gulf Turbine Services, enhancing safety

protocols and streamlining operations in several key ways.”

LockOut ID has changed the game for our LOTO. There are 2 keys to a successful LOTO process.

1. Simple and easy to understand

2. Secure

Secure is never a problem that we face. Our we and our clients rigorously check systems to ensure those in our charge are as safe as

can be from any energy source. However, difficulty level is always a struggle. Every customer we service as a different LOTO system.

While trying to manage the learning curve of a new system, LockOut ID has made sure that our end is streamlined and simple. We have

contractors from all over the world with interesting and diverse backgrounds which come along with interesting names.

With this system I don't have to find the sign in sheet or try to decipher the name on the tag and nearly illegible phone number on the

lock. I simply scan the tag and a name, face, and phone number appear. Then I can instantly contact the person I need and inform them

of any LOTO updates they need to be aware of. At the end of the job I collect the tags, erase the database, and I am ready to start the

next job with a whole new crew. Key #1: SIMPLE!

I used LOCKOUTID at the McDonough Block 5 MIs in the spring of 2023 and I have observed it in full use at the Lake Charles Spring 2024

TIs. Compared to handwritten information tags the LOCKOUTID is far superior when there is a need to identify a lock owne r. The

LOCKOUTID system helps keep the LOTO boxes organized and visible. The compact size of the tag provides a clean, professional look to

the LOTO satellite box area and the electronic interface ensures all identification attributes are legible and accessible, including a

photograph. Anyone with a smartphone can scan any tag instantly and know exactly to whom the tag/lock belongs. Creating the tags is

a simple task that can be performed onsite.”